|

|

|

| Spherilastik Bearings |

|

| Features / Applications |

A heavy duty flexible bearing which combines highload carrying capacity with the ability to accommodate torsional and angular movements in all planes without lubrication and metal-to-metal wear. |

Spherilastik bearings with through holes or solid centre members are available in a range of sizes as detailed in this leaflet. |

Typical uses include traction and braking reaction rods for rail, road and off-road vehicles, hydraulic damper fixings and other applications where a high duty bearing of compact size is required. |

|

|

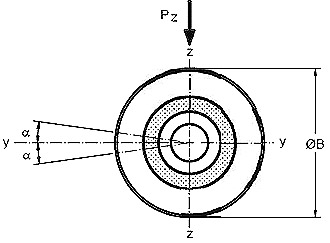

| Centre Bore |

|

The diagram shows overall and fitting dimensions only. It is recommended that a drawing of the product is obtained before ordering. |

|

|

|

Part No. |

13/1316 |

13/1962 |

13/2201 |

13/2047 |

13/2108 |

13/1295 |

13/2106 |

Pz kN |

34 |

34 |

34 |

35 |

53 |

53.5 |

58 |

Kz MN/m |

70 |

70 |

70 |

32 |

83 |

83 |

100 |

α° |

8 |

8 |

8 |

10 |

8 |

8 |

8 |

Kxx kNm/rad |

0.9 |

0.9 |

0.9 |

3.2 |

2.6 |

2.6 |

2.8 |

θ |

6 |

6 |

6 |

8 |

6 |

6 |

6 |

Kyy kNm/rad |

0.9 |

0.9 |

0.9 |

2.9 |

2.6 |

2.6 |

2.8 |

A mm |

25.4 |

25 |

25.4 |

38.1 |

41.3 |

41.3 |

28.6 |

B mm |

66.7 |

66 |

66.7 |

104.8 |

90.5 |

90.5 |

90 |

C mm |

47.6 |

48 |

47.6 |

76.2 |

101.6 |

70 |

70 |

D mm |

54 |

54 |

54 |

82.6 |

65 |

73.2 |

76.2 |

Mass weight, kg |

0.84 |

0.83 |

0.41 |

3.2 |

1.5 |

2.2 |

1.8 |

|

|

| General guidance notes for selection: |

| 1. Properties quoted for the components in this leaflet relate to continuous steady loading or deformation conditions. |

| 2. For continuous dynamic cyclic loading or deformation, the maximum values should be reduced to approximately 30% of the figures quoted, depending on frequency. |

| 3. For medium and low incidence loading and deformation, the tabled values may be increased up to 2 to 3 times. |

| 4. Combined stressing in the different modes and the effects of stress reversals may require a more critical assessment. |

|

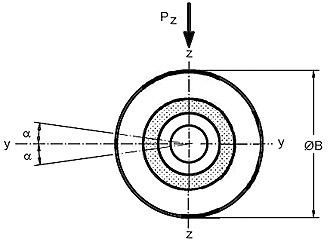

| Centre Bore |

|

The diagram shows overall and fitting dimensions only. It is recommended that a drawing of the product is obtained before ordering. |

|

|

|

|

Part No. |

13/1006 |

13/1285 |

13/1180 |

13/0894 |

13/1680 |

13/1339 |

13/1990 |

Pz kN |

58 |

78 |

110 |

180 |

220 |

400 |

425 |

Kz MN/m |

93 |

90 |

100 |

100 |

260 |

350 |

470 |

α° |

8 |

8 |

10 |

9 |

6 |

7 |

7 |

Kxx kNm/rad |

2.8 |

4.5 |

7 |

30 |

15 |

26 |

21 |

θ |

6 |

7 |

6 |

8 |

5 |

6 |

6 |

Kyy kNm/rad |

2.8 |

3.8 |

6 |

20 |

13 |

20 |

18 |

A mm |

28.6 |

38.1 |

44.5 |

76.2 |

50.1 |

114.3 |

60 |

B mm |

90.5 |

104.8 |

127 |

200 |

127 |

200 |

150 |

C mm |

70 |

76.2 |

101.6 |

152.4 |

101.6 |

152.4 |

120 |

D mm |

54 |

54 |

54 |

82.6 |

65 |

73.2 |

76.2 |

Mass weight, kg |

2.2 |

3.4 |

6.6 |

21.9 |

6.3 |

19.4 |

11.5 |

|

|

| General guidance notes for selection: |

| 1. Properties quoted for the components in this leaflet relate to continuous steady loading or deformation conditions. |

| 2. For continuous dynamic cyclic loading or deformation, the maximum values should be reduced to approximately 30% of the figures quoted, depending on frequency. |

| 3. For medium and low incidence loading and deformation, the tabled values may be increased up to 2 to 3 times. |

| 4. Combined stressing in the different modes and the effects of stress reversals may require a more critical assessment. |

|

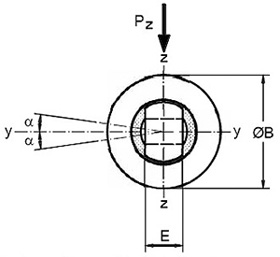

| Trunnion Type |

|

The diagram shows overall and fitting dimensions only. It is recommended that a drawing of the product is obtained before ordering. |

|

|

|

|

Part No. |

13/2092 |

13/2202 |

13/2203 |

13/2181 |

13/2192 |

13/2033 |

13/2223 |

Pz kN |

12 |

34 |

34 |

58 |

58 |

75 |

80 |

Kz MN/m |

34 |

70 |

70 |

90 |

90 |

150 |

100 |

α° |

8 |

8 |

8 |

10 |

8 |

8 |

8 |

Kxx kNm/rad |

0.17 |

0.7 |

0.7 |

2.8 |

2.8 |

2.8 |

4.5 |

θ |

6 |

6 |

6 |

6 |

6 |

6 |

7 |

Kyy kNm/rad |

0.2 |

0.9 |

0.9 |

2.8 |

2.8 |

2.8 |

3.8 |

A mm |

30 |

35 |

35 |

48 |

48 |

40 |

50.5 |

B mm |

45 |

66.7 |

66.7 |

90.6 |

90.6 |

84 |

104.8 |

C mm |

35 |

47.6 |

47.6 |

70 |

70 |

65 |

76.2 |

D mm |

105 |

120 |

126 |

190 |

170 |

155 |

170 |

E mm |

12 |

20 |

20 |

30 |

30 |

20 |

30 |

F mm |

75 |

90 |

96 |

140 |

130 |

120 |

130 |

G mm |

13 |

13 |

17 |

20.5 |

20.5 |

16.5 |

19 |

Mass weight, kg |

0.47 |

1.14 |

1.02 |

2.8 |

3 |

2.8 |

5.8 |

|

|

| General guidance notes for selection: |

| 1. Properties quoted for the components in this leaflet relate to continuous steady loading or deformation conditions. |

| 2. For continuous dynamic cyclic loading or deformation, the maximum values should be reduced to approximately 30% of the figures quoted, depending on frequency. |

| 3. For medium and low incidence loading and deformation, the tabled values may be increased up to 2 to 3 times. |

| 4. Combined stressing in the different modes and the effects of stress reversals may require a more critical assessment. |

|

| |

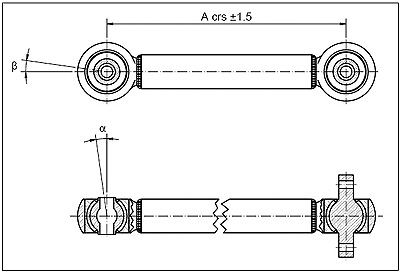

| Control links |

|

Features/Applications

|

A range of Control Links incorporating Spherilastik Bearings is available and typical sizes are listed below. Further details are available on request. |

|

|

|

Part No. |

Spherilastik Part No. |

Type |

A1mm |

Nominal P. max kN |

β |

α |

Mass weight

|

Degrees |

Degrees |

kg |

13/2233 |

13/2192 |

2 |

490 |

58 |

6 |

8 |

12 |

13/2235 |

13/2107 |

2 |

644 |

58 |

6 |

8 |

14 |

13/2154 |

13/1006 |

1 |

673 |

58 |

6 |

8 |

15 |

13/2280 |

13/1006 |

1 |

720 |

58 |

6 |

8 |

16 |

13/2369 |

13/2192 |

2 |

1315 |

58 |

6 |

8 |

27 |

|

| Properties quoted are for 60H rubber compound |

| General guidance notes for selection: |

| 1. Properties quoted for the components in this leaflet relate to continuous steady loading or deformation conditions. |

| 2. For continuous dynamic cyclic loading or deformation, the maximum values should be reduced to approximately 30% of the figures quoted, depending on frequency. |

| 3. For medium and low incidence loading and deformation, the tabled values may be increased up to 2 to 3 times. |

| 4. Combined stressing in the different modes and the effects of stress reversals may require a more critical assessment. |

|